Developmental results

- Flexible OLEDs on stainless steel foil

- Flexible OLED devices on EXPEEK® film with high-temperature torelance

- Laminating encapsulation for flexible devices

Flexible OLEDs on stainless steel foil

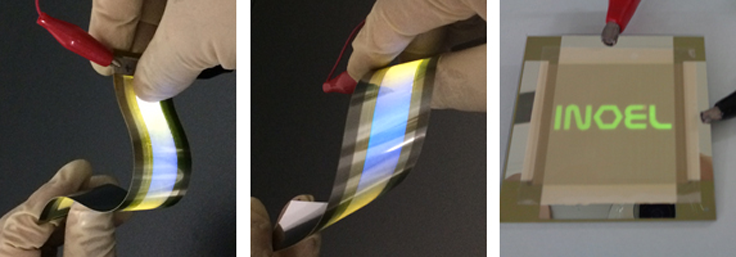

Technological developmental results:Flexible OLEDs on stainless steel foil

(In cooperation with: NIPPON STEEL & SUMITOMO METAL CORPORATION)

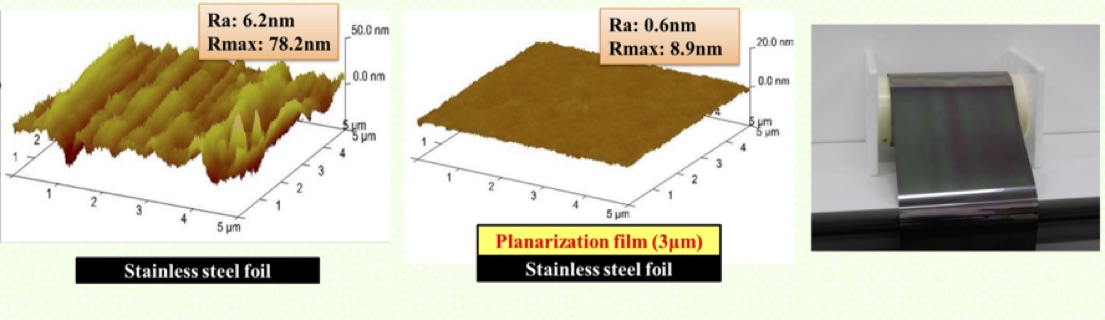

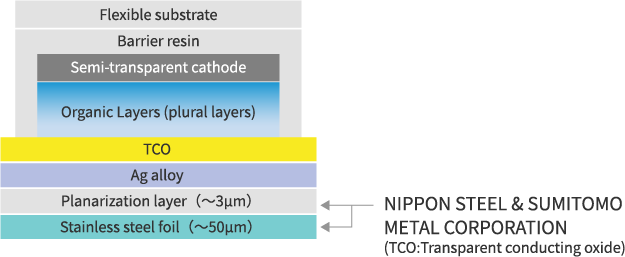

Stainless steel foil has several advantages, such as temperature resistance, chemical stability, excellent gas barrier properties, etc. However, the surface smoothness has been a big issue regarding application to OLED devices. To solve this issue, NIPPON STEEL & SUMITOMO METAL CORPORATION GROUP developed a surface planarization technology for stainless steel foil (1-4).

Technological features

Advantages of the stainless steel foils of NIPPON STEEL & SUMITOMO METAL CORPORATION GROUP (1)

- Thickness: 50 μm

- Excellent surface smoothness (Ra to 0.6 nm)

- Excellent temperature and process resistances

- High gas barrier ability

Developed technologies

Flexible OLEDs on stainless steel foil

A stainless steel foil with an inorganic-organic planarization layer developed by NIPPON STEEL & SUMITOMO METAL CORPORATION GROUP was applied to flexible OLED devices.

References:

[1] N. Yamada, S. Yamaguchi, J. Nakatsuka, Y. Hagiwara, K. Uemura, IDW’15, FMC3-1 (2015).

“Planarized Stainless Steel Foil for Flexible Substrate”

[2] M. Koden, T. Furukawa, T. Yuki, H. Kobayashi, H. Nakada, IDW/AD’16, FLX3-1 (2016).

“Substrates and Non-ITO Electrodes for Flexible OLEDs”

[3] Y. Hagiwara, H. Itoh, T. Furukawa, H. Kobayashi, S. Yamaguchi, N. Yamada, J. Nakatsuka, M. Koden, H. Nakada, IDW/AD’16, FLXp1 – 5 (2016).

“Roll-to-Roll Processing of Silver/ITO Continuous Deposition on Planarized Stainless Steel Foil”

[4] Y. Hagiwara, T. Furukawa, T. Yuki, S. Yamaguchi, N. Yamada, J. Nakatsuka, M. Koden, H. Nakada, IDW’17, FLXp1-9L (2017).

“Roll-to-Roll Patterning of Reflective Electrode on Planarized Stainless Steel Foil”

Collaboration

NIPPON STEEL & SUMITOMO METAL CORPORATION GROUP

Related programs

- Yamagata University Flexible Electronics Japan-Germany International Collaborative Practical Utilization Consortium (YU-FIC) (Oct. 2017 to Mar. 2021)

- MEXT: Construction Program of Open Innovation Organization (FY2018 to FY2022)

Publications

- Yamagata University, “JFlex 2019” exhibition (Tokyo, Jan. 2019)