Research Groups

Research Groups

INOEL’s eight domains of research & development

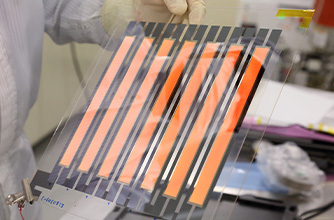

Next Generation Wet-processed Thin Films :

Achieving New Thin Films for GX and DX by Wet Processes

We are researching and developing highly functional thin films by wet processes, aiming for environmentally friendly (GX) and digital manufacturing (DX). We achieved the world’s highest performance of water vapor barrier film by wet process (2022). This technology will contribute a wide range of industries, including flexible devices and the packaging field. We are also developing OLED panels using printing processes. We are promoting research on new thin films, both organic and inorganic, focusing on wet processes for next generation technology. (Professor Yoshiyuki Suzuri, Assistant Professor Sun He, Researcher Song Luyang )

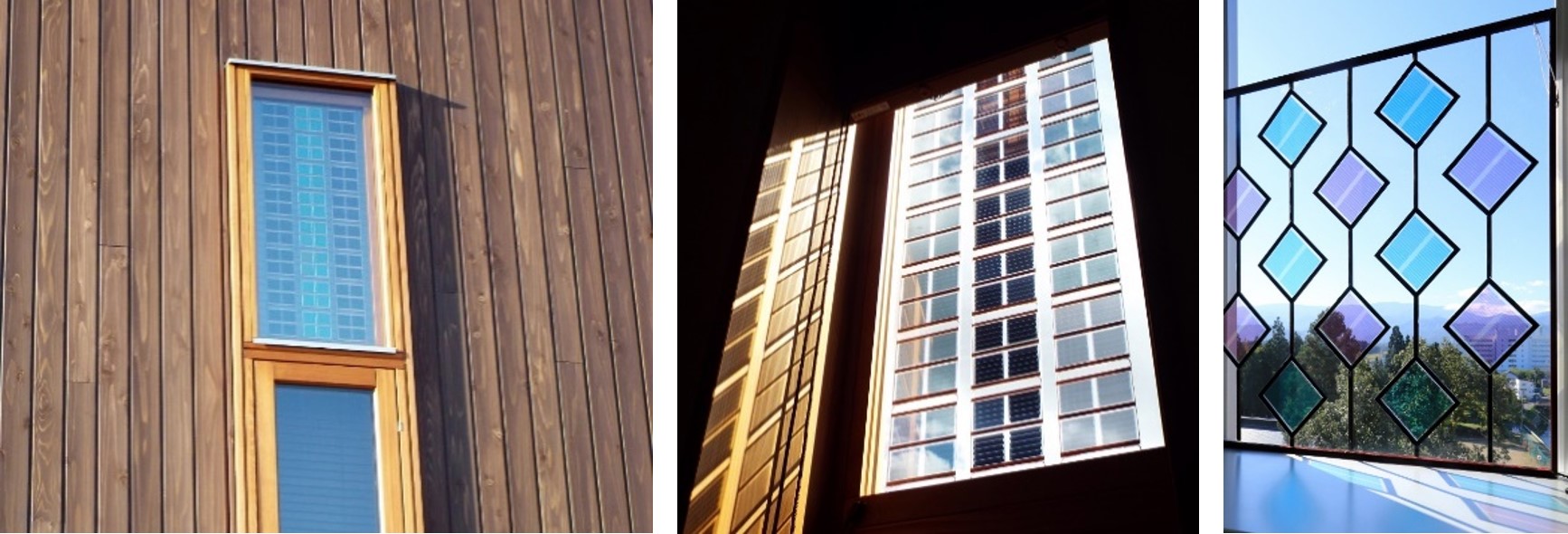

Organic & Next-generation Solar Cells (OPV, PVSC):

Realizing thin, light, transparent and highly-efficient solar cells

We are developing organic photovoltaic solar cells (OPVs) and perovskite solar cells (PVSCs) that have promising features such as thinness, light weight, flexibility, translucency, designability, and power generation characteristics under indoor light. In collaboration with Frontier Center for Organic Materials, companies, and research institutes, we explore, develop, and evaluate materials using appropriate device structures. Specifically, we are investigating organic photovoltaic materials, non-fullerene acceptors, charge transport materials, self-assembled monolayer molecules, and perovskite materials. We are also developing technologies for single cells with high efficiency and reliability, transparent solar cells, and tandem solar cells. We are aiming for applications such as see-through solar panels for windows, flexible solar panels, and energy harvesting cells for IoT devices. (Prof. Takeshi Sano)

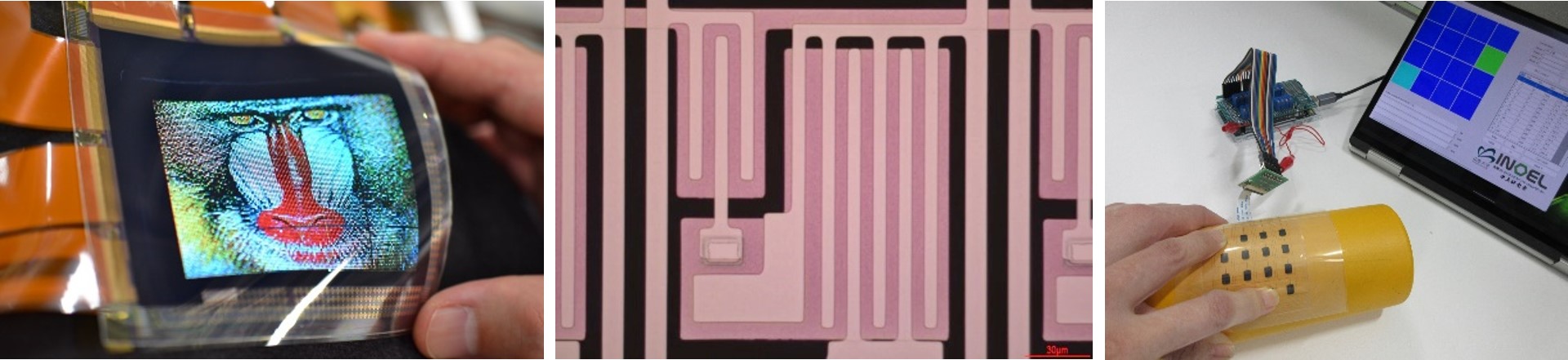

High density thin film device :

Realizing new thin film electronic devices

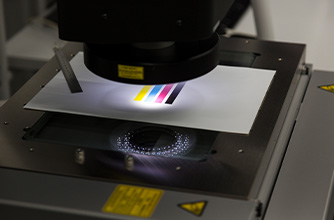

We are developing processes that use printing methods such as inkjet and offset to form metals, insulators, and organic materials with fineness and quality comparable to photolithography.

We are also developing the use of this technology to fabricate high-density thin film devices such as stacked circuits, digital circuits, organic thin transistors, and physical sensors.

These high-density thin film devices are expected to be applied to backplanes such as large-screen OLSD displays and flexible electronic paper, and sensors that have the tactile sensation of human hands and feet.( Reseach Professor Makoto Mizukami, Associate Professor Yasunori Takeda )

Flexible Technologies :

Creating new value with flexible technology

Through “Needs First” academia-industry collaboration, we develop key technologies for flexible organic electronics products that create new values such as thin thinness, light weight, flexible design, etc. We develop world-leading cutting-edge technologies in the fields of flexible substrates (ultra-thin glass, stainless steel foil and barrier films), gas barrier(deposition technology, evaluation technology), flexible encapsulation and printing. In addition, by applying the developed technologies, we fabricate various flexible devices such as flexible OLED and Solar cell. (Prof. Takeshi Sano, Miho Sugimoto, Academic-Industrial Collaboration Associate Professor)

Flexible Electronics :

Creating new value with technology of flexible electronics

Through “Needs First” academia-industry collaboration, we develop key technologies for flexible organic electronics products that create new values such as thin thinness, light weight, flexible design, etc. We develop world-leading cutting-edge technologies in the fields of flexible substrates (ultra-thin glass, stainless steel foil and barrier films), gas barrier, flexible encapsulation, printing and roll-to-roll. In addition, by applying the developed technologies, we fabricate various flexible devices. ( Tadahiro Furukawa, Reseach Professor)

Inkjet :

Creating new manufacturing with printing technology

Inkjet that can precisely jet ink droplets whose diameter is a fraction of human hair and in an invisible size to freely draw images and patterns having millions, tens of millions or hundreds of millions of dots is a kind of magic pen. Capable of precisely arranging droplets by digital control is attracting attention as a next-generation production technology known as digital fabrication, including not only the creation of documents or photographic images but also illustrations on cloth and construction materials and the manufacture of electronic elements and 3D objects. We are engaged in the development of technology to jet high-viscosity ink and thorough analyses of phenomena where droplets are formed in an infinitesimal period of time in microseconds. (Shinri Sakai, Academic-Industrial Collaboration Professor)

Invention of the advanced batteries having the high safty and energy density

Lithium-ion batteries have become an important tool in our lives such as portable devices and electric vehicles. The development of the advanced batteries having the high safety and energy density have atrracted much attntion to enrich our lives. Our group is working with the companies from the research and development of the advanced materials and batteries to the construction of the mass production processes for the batteries. The characteristics of our group is to develop a consistent process from basic research to the mass production for the batteries. (Masanori Morishita, Research Professor)

Soft Sensing Devices

– Connecting People and Information –

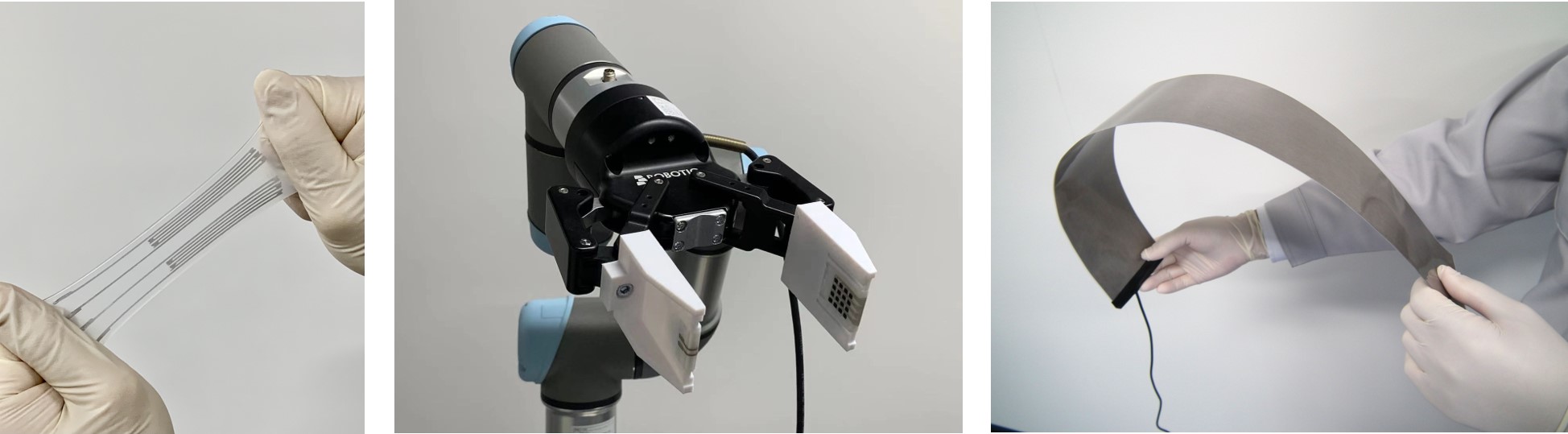

We are conducting research and development of soft sensing devices based on organic electronics. Flexible and stretchable soft sensors are expected to be used in a variety of fields, including healthcare and robotics, as key devices connecting people and information. Thin and large-area soft sensors can be incorporated into living spaces such as chairs, beds, and walls, and are attracting attention as a technology that can improve the convenience of human life without making the user aware. Our research group has technologies such as design and development for sensor devices and integrated circuits, fabrication methods using printing processes, signal processing and analysis technology for sensing data, and integration of these technologies into product-based prototyping. (Daisuke Kumaki, Research Professor)